Walzwerk Rolling Press: Minting Defects on Coins, p. 2 (Story page 50)

Displacement of Coin Design, Klippe and Plate Coins, Bent Coins

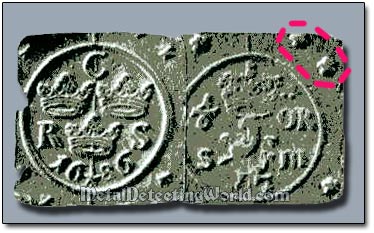

Also on the right picture, one can see two stars (at 10 o'clock) on the coin. These stars were also engraved on rollers for two reasons. First, engraving stars in the empty areas between the engraved dies would produce more embossed elements on a copper strip. This could prevent accidental slipping of rollers and ensure the uniform impression of coin designs.

Secondly, the stamped stars would mark the "webbing" - the strip of copper that was left over after the coins were punched out of it, which would be recycled into new sheet copper. If would be difficult for anyone to sell the marked copper webbing if it was smuggled out of the mint.

The same stars can be seen on the rectangular 1686 1/6 Öre coin shown below. Most likely the coin punching machine was temporarily out of service, and the mint workers manually cut the rectangular pieces bearing the stamped designs of the round 1/6 Öre coin out of the copper strip. Such pieces are rare.

Same Stars Are Visible on Rectangular 1686 1/6 Öre Coin

These rectangular coins should not be confused with Klippe coins (klippingar) which are also rectangular but bear their own unique designs without stars (copper klippe coins of 1624-27).

Copper coins of two different denominations were simultaneously produced by one walzwerk machine. An imprint of a large coin would be surrounded by the imprints of smaller coins on the copper strip. This was done to fill the space up to the maximum so less copper would go into recycling; thus, lowering the cost of minting process.

Also for the purpose of lowering the cost of minting coins and to facilitate the export of copper, "Plate Money" (Plåtmynt) were also produced in Sweden. The plate money were fabricated by the same Klippe method and allowed production of coins of large denominations. Each plate coin bore a few round coin designs stamped on it by the walzwerk press.

Example of Swedish Plate Coin - 1747 1/2 Daler, King Frederik I ("FRS" - Frederik Regis Svecia)

The largest and heaviest plate coin was minted during the reign of Swedish Queen Christina in 1644. Its weight was 20 kg (44 lbs)! (Try to send a kid to the store to buy a loaf of bread with such a coin! :)) Issuance of this gigantic coin - 10 Dalers, was justified by the idea that it was easier to carry a single coin-plate than 350 1 Öre copper coins, nothing to say about the amount of time wasted for counting them during transaction. To carry the heavy metal plate coins, the custom-made sleds were used.

The plate money of six denominations, Ruble (100 Kopecks, weight = 1.63 kg), Poltina (50 Kopecks, 0.8 kg), Polupoltina (25 Kopecks, 0.4 kg), Grivna (10 Kopecks, 0.163 kg), 5 Kopecks (0.081 kg) and 1 Kopeck (0.016 kg), were also minted in Russia from 1725 to 1727.

The walzwerked coins sometimes show another peculiarity - a curvature along one axis, as shown on a picture of a bent coin below. Such coin bends could be caused by various mishaps occurred with the Walzwerk roller during operation, or during the backing-up procedure deliberately carried out by an operator.

Slightly Bent Copper Coin

The "Walzwerk" coining machine was invented in Hall in Tirol, Austria, in the 1550s. As the technology was developing, the die engraving on rollers was replaced by implementation of removable dies. In the following century the Walzwerk coin-minting machine was widely used in Western and Northern Europe. Also a variation of the machine - the "Walzenprägung" (the "embossing roller") using narrow sheet metal strips, was utilized for minting coins of higher denominations and silver content.

Despite the emergence and use of other contemporary innovative coin-striking machines, such as Screw Press, the Walzwerk machine remained in use at the Austrian mints until 1754, and South-German mints used it until 1790. In Sweden, the "Walzwerk" coining machine was introduced in 1625, just one year after the first Swedish copper coin - rectangular 1/4 Öre, called "fyrk", was manually hammered at the Säter mint. However, the klippingar of other metals had already been produced prior to that time in Sweden. The first silver klippe coin of denomination 15 Öre was hammered as early as 1543, and the first gold klippe coin - 8 Marks, was hammered in 1587.

Initially the Walzwerk machine was used for minting the copper rectangular "fyrks" to achieve better quality of coins and greatly increase their production. In 1627, a mint master Mark Cook from Koenigsberg (today Russian city of Kaliningrad) was appointed by the king Gustav II Adolf to set up the Walzwerk technology for minting round coins at Säter and Nyköping mints. Later the "Walzwerk" coining machine was employed at many mints in Sweden and its dominions, and remained in use until 1777.

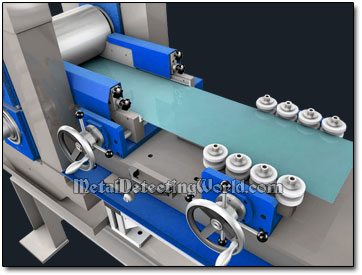

The principle of walzwerk was also used for fabricating the sheet metal and sheet metal strips for coinage. And today, the Walzwerk rolling technology is still widely employed in steel mills and many other industries.