Search Coils for Metal Detectors, page 20

Sealing Search Coil Cover To Secure Against Dirt and Moisture

Within the first year of using my metal detector, I started noticing short false signals while swinging the search coil in the air. No matter what program settings I was using, the false signals would not disappear.

The puzzle was solved easily when I finally detached the coil cover to clean it inside. As a substantial amount of dirt, sand, and small rock fragments fell out, not only the coil became lighter but also the false signals disappeared. The dirt that got inside, between the search coil and coil cover, through the gap consisted of mineralized soil and caused the false signals' appearance.

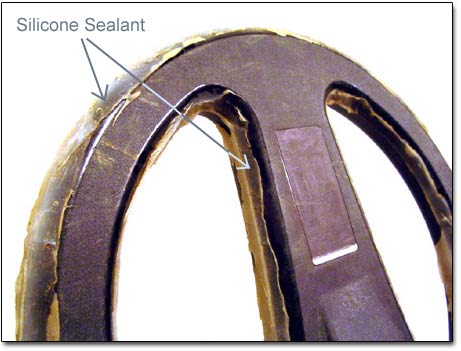

Prior to that discovery, I used either duct tape or electrical tape to prevent the coil cover from falling off during metal detecting. Now, to seal the gap and keep the coil cover secured, I used the silicone sealant because, for its water resistance and flexibility, it is the most reliable way to seal the gap against the elements. At the same time, the silicone sealant cushions movements between search coil and coil cover resulting from temperature changes and mechanical shocks.

Silicone Sealant

![]()

Your objective is to seal hermetically the gap between the search coil and its coil cover (skid plate). First you have to make sure adhesive surfaces are dry and free of dirt, grease and dust as they would impair the silicone sealant�s adhesion and curing. Put the cover on the search coil tightly and secure it with electrical tape if necessary.

Then you cut the plastic applicator nozzle with scissors at an angle to achieve a 1/8-inch hole in the end. Puncture the seal on the silicon tube with a nail. Screw the nozzle on the tube clockwise until it becomes tight. Place the nozzle on the area for sealant, then squeeze it to apply a small but constant bead of silicone filling the gap all the way around the circumference.

The first mistake one can make is applying too much silicone, this is easily done and can make a complete mess. So apply the silicone sparingly. If you miss a little bit you can always go back afterwards and fill the gap. Use a small spatula (you can cut it from the plastic bottle with scissors), paper or a cloth to remove the excess silicone. If necessary, use the washing up liquid and draw it along the bead of silicone.

While sealing, do not inhale the fumes over a long period or in a high concentration. Make sure there is adequate ventilation. If the eyes or mucous membranes come into contact with uncured silicone rubber, rinse well with water to prevent inflammation. Cured silicone rubber can be handled without any health risks.

Wait until the next day and wipe the coil clean with a damp cloth. If you want the coil to look neat, wipe off the residue with a cloth moistened in a solvent such as white spirit or ethanol, and follow safety instructions. It is best to save the remaining sealant as it always comes in useful. Do this by screwing a tight fitting screw into the nozzle, this stops the air getting to the silicone and curing it.

Clear Silicone Sealant On Standard Minelab 10.5" Search Coil

Brown Color Silicone Sealant On Minelab 7-1/4" Search Coil

Since I sealed the coil covers on all my metal detectors, I have not had any problems so far. Unlike other joint fillers, silicone sealants have the best resistance to weathering and aging. Not even years of open-air weathering will change their physical properties. The outdoors silicone sealant, both clear and in different colors, is sold in any hardware store.

Happy Hunting!

Make a Donation

Please help me stay afloat, afford more metal detecting trips with field-tests and experiments to create more informative articles, useful tutorials and helpful guides for detectorists, and maintain this website - the most informative hobby resource on the web! Since I do not have any steady income, any donation matters to me a lot! Thank you kindly!

Clicking on the donate button will take you to a donation page powered by Donorbox and dedicated to my website (MetalDetectingWorld.com). The donation page is PCI-compliant, secured by SSL/TLS, and has a simple form to fill out. Donorbox does not store any card or bank data. Credit card information is encrypted and tokenized by the Stripe payment processor.

This website would not exist without the advertisements we display and your kind donations. If you are unable to support us by viewing our advertisements, please consider making a Donation to ensure the future of this website. By helping me keep this website alive and growing, you will sure help many detectorists around the world as well!

ANNOUNCEMENT:

In January of 2020, I started a one-time fund-raising campaign in attempt to accumulate enough money to buy a simple but reliable 4x4 vehicle. My old 4x4 car (made in 1995) had faithfully served me for 10 years before it eventually went beyond repair last October. Without a 4WD, I will not be able to get to my hunt sites and test-plots hidden in the remote wooded areas inaccessible by a regular car.

Unlucky for me, those sites are the only locations available and suitable for my field-work which results in informative articles you can find on this website. For the past 10 years, my usual field-work has consisted of field-testing the latest metal detectors and accessories, experimenting with some of them, and devising new effective search methods that meet the requirements of the new metal detecting reality.

Before my car died, I managed to finish a couple of interesting detector-testing projects which will be covered in my upcoming articles. But other equally important projects that I was working on were not completed and had to be postponed until the Spring 2020. I hope that this fund-raising campaign will help me get a decent 4x4 by then so that I will be able to resume my work and to write more new articles, tutorials and guides based on data gathered through testing and experimentation.

If you find my website useful and would like it to provide more essential info for you and other detectorists worldwide, please consider chipping in $5, $20, $50 or whatever you can afford to keep MetalDetectingWorld.com growing in 2020. I promise you, it will be money well spent. Thank you.

Donate- Please help me promote this guide:

If you would like to follow me on Twitter, please press a button:

I have my profile page on

where you can share your thoughts on this guide, ask me a question, or place a friend request.I also have my profile pages on Pinterest, LinkedIn, Tumblr, Reddit and Delicious

and my "Metal Detecting World" page on Twitter, Pinterest and Tumblr

I no longer maintain my old Facebook page