How To Clean Coins with Electrolysis - A Detailed and Illustrated Tutorial, page 8

Making a Simple Coin Electrolysis Machine of "CLASSIC" Type

(...CONTINUED from Previous Page)

Use Splice Connectors To Connect Wires

If you do not use a soldering-iron to connect the wires, you still have to make strong wire connections. Of course, you can just simply twist the wires together and then wrap electrical tape around the connecting points. Or you can use crimp-on insulated splice butt connectors, especially if the wires of different gauges (14awg-16awg) are involved.

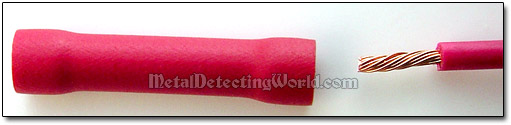

A Butt Splice Connector Will Do the Job

A set of side cutting pliers with a crimp-on part will help you compress both ends of the connector with the wire terminals inside to ensure a good electrical contact.

Using Side Cutting Pliers for Compressing a Butt Splice Connector

Insert each wire end into a metal tube inside the butt splice connector.

Inserting Wire Ends Before Crimping

Crimp the connector making sure that the wire does not slide out from either end.

Crimped Butt Splice Wire Connector

Repeat this procedure for connecting the negative (WHITE) wires.

Blue Butt Connector for Splicing Negative Wires