Clean Coins and Jewelry with Electrolysis - A Detailed Illustrated Tutorial, page 23

Effects of Coin Electrolysis on Dug Copper Coins with Verdigris Coating

(...CONTINUED from Previous Page)

• Results of Cleaning Coin #2 with Ammonia Bath and Electrolysis

The dug copper coin #2 shown below had been also damaged by verdigris. Unlike the coin #1, the coin #2 was not hard-brushed with the nylon brush; only dirt was brushed with a soft toothbrush and rinsed off under running water.

Second Corroded Dug Coin, ca. 1812, To Be Cleaned by Electrolysis

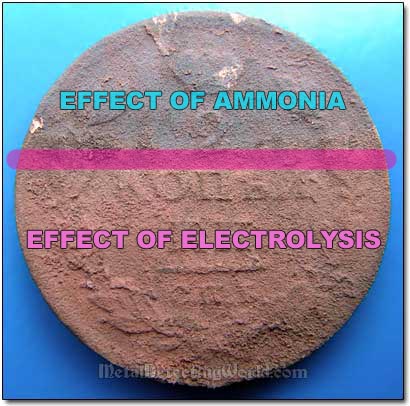

To see if there would be a difference in the coin surface appearance after the coin is cleaned by two different methods, one part of the coin was cleaned by immersing it into the Ammonia solution (this method is described here). The untreated part of the coin #2 was cleaned with electrolysis using the "Pipe" setup.

Effects of Two Coin Cleaning Processes - Electrolysis and Ammonia Bath

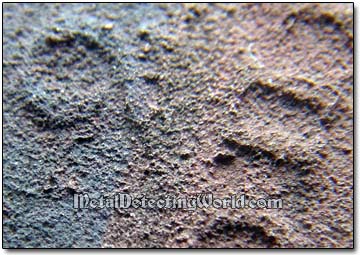

Surfaces of two cleaned areas were examined under a magnifying glass and did not seem to be different from one another, except for their colors.

Coin Surface is the Same in Both Areas

Both surfaces exhibit the same roughness, proving that neither of two cleaning methods caused any additional damage to the coin surface that had been severely damaged by corrosion and hidden by the resulting verdigris coating prior to cleaning.