Electrolytic Removal of Rust - A Detailed Illustrated Tutorial, p.25

4. The Process: After-Electrolysis Treatment of Iron - Relic's First Derusted Half

Before withdrawing your de-rusted iron object from the electrolysis container, you MUST UNPLUG the electrolytic setup first! And put your protective RUBBER GLOVES on!

It is a good idea to skim off the crud on the surface before pulling the object.

Now you do the following:

1) Rinse the iron object.

Following the electrolytic treatment, it is necessary to remove insoluble oxide sludge and chemical residue including remnants of electrolyte through intensive rinsing. De-ionized or distilled water would be ideal for rinsing, but I had only tap water at hand, and that was what I used.

2) Remove the loosened rust off the surface.

The layer of loosened rust could be simply pushed off using finger pressure to reveal a solid black metallic core. Use an awl for removal of less loosened rust.

Lifting Rust Off the Surface with Awl

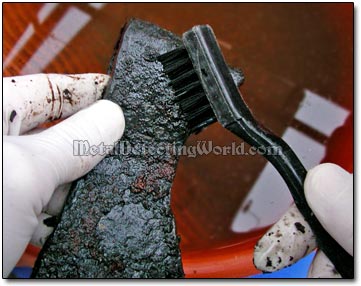

3) Wire-brush the remaining rust off the surface with a metal wire brush; followed by rinsing.

Gently Scrubbing Rust Off the Electrolyzed Half

A brass bristled brush is the best for cleaning the iron artifacts after they have been through electrolysis because it will not score the iron surface.

A brass bristled brush is the best for cleaning the iron artifacts after they have been through electrolysis because it will not score the iron surface.

4) Remove the black coating off the surface.

It can be done with a nylon brush (see details in the "What Is Black Coating and..." section on page 27). Do not let the black coating get dry, otherwise you will have hard time removing it. Rinse the object afterwards.

Brushing Black Coating Off

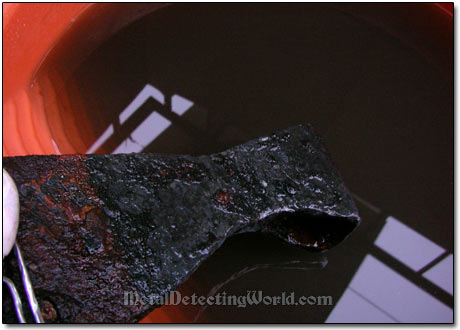

Visually inspect the object's de-rusted half. If further electrolysis is not necessary - you do not see any rust remaining, continue with the next step. Otherwise, run additional session(s) to derust this half completely.

This De-Rusted Half of Axehead Needs Additional Electrolysis Session(s)

5) Dry the de-rusted area rapidly.

There are two quick ways to dehydrate the iron surface: 1) by using a hair blower (dryer), or 2) by using acetone - the best way! For a quick treatment of just a half of the artifact, I use the hair blower, but for no longer than 30 seconds.

Drying De-Rusted Half

After having been dehydrated, the iron surface is in a reactive state and quickly rusts on exposure to air. In fact, if you delay with putting some protective coating on the de-rusted half of your iron object, you will see new rust forming almost immediately! In order to prevent the rapid formation of rust, contact with air should be minimized, and a sealant or insulating coating is applied right away.

6) Protect the surface with WD-40.

While the second half of the iron artifact undergoes electrolytic de-rusting, the first (de-rusted) half will be exposed not only to air, but also to harsh environment of caustic vapors and heat. That is why the de-rusted half should be protected for sure.

The WD-40 best serves the purpose: it disposes the water molecules from the iron surface, and provides a strong insulating coating for protection. You only need to make sure that you do not spray too much WD-40 on the de-rusted half, otherwise the electrolyte will be heavily contaminated when the artifact is reinstalled in it. A light contamination will certainly occur, but it is nothing to worry about.

Spraying WD-40 onto Derusted Half to Prevent Re-Rusting

NOTE: The WD-40 will not last forever as it tends to evaporate, slowly but truly. After your entire iron object is de-rusted, a longer-lasting rust inhibitor should be applied (see details on page 29). BTW, "WD-40" stands for "Water Displacement - 40th Attempt".