Electrolytic Rust Removal - A Detailed Illustrated Tutorial, page 30

6. Conservation of Derusted Artifacts: Applying Rust Inhibitor, Storage of Iron Relics

3) Applying Rust Inhibitor for Long-Term Prevention of Rust

If the rust inhibitor is in gel form, shake the bottle before use, and do it before you take the iron object out of the acetone bath. Make sure you put on your gloves and proceed in a well ventilated area or outside your house.

It is important to read the instructions about the time required for the product to get completely dry after application. If it takes a couple of days, you do not have to put it on the artifact sparingly as you will have plenty of time to wipe off the excess amount.

If the product dries up quickly, putting it on too thick will form a very sticky surface afterwards. So it is up to your discretion what amount of gel to apply.

Pouring Rust Inhibitor Gel onto Artifact

Try not to inhale the vapor (especially when you are using a spray-on product) that comes off while you are spreading the rust inhibitor all over the iron artifact with a small paint brush. Make sure you get the jelly substance in all enclosed spaces without leaving a single spot uncovered.

Spreading Gel onto Artifact with Paint Brush

Because the rust inhibitor I used would dry out only in two days, I applied a thick layer of it, brushed it into the surface, and let it settle in for a minute.

Thick Layer of Rust Inhibiting Coating on Derusted Relic

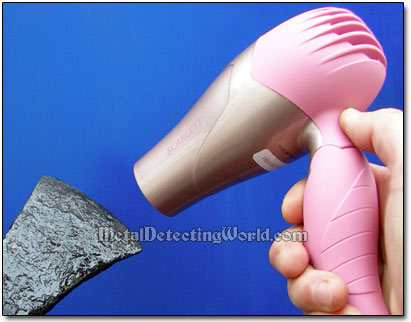

Then I mopped off as much gel as I could using a rag or cloth made of SYNTHETIC material (cotton or paper towels usually do not work well). To speed up the process of dehydration a little, for 10 minutes I used a hair dryer set up on low, so the coating would get slightly solidified.

Drying Derusted Artifact with Hair Blower

I let the coating dehydrate naturally until the iron surface felt dry and firm on touch. And that is it!

My metal detecting find - the 17th century axehead, turned from the heavily rusted, unappealing piece...

Rusted Axehead Before Electrolysis

...into a presentable collectible that now can be either displayed or sold on eBay, or stored until later. (BTW, a word presentable first appeared in English language in 1626 - the same year this axehead was probably made.)

A Nice Addition to My Collection of Relic Tools

Proper Storage of Iron Relics and Artifacts

Proper storage of iron artifacts is as vital for their long-lasting protection as the conservation and preservation treatments described above. There is not a single sealant or insulating coating that can withstand a long-term exposure to adverse ambient environment. To avoid failing of the protective coatings, store the artifacts in a place where:

• Humidity should be below 55% (use a Humidity Sensor to be on a safe side) - no storage in a damp basement!

• Temperature does not fluctuate rapidly, and does not get hot - no storage in an attic!

• Moisture (condensation) can NOT build up on the artifacts - no storage inside sealed plastic containers or bags!

• Dust can NOT accumulate or get to the artifacts - use plastic or cloth curtains, and inert foam padding.

• Direct Sun Light cannot get in.

It is not that difficult to preserve your relics if you put a little effort into it. Along with the after-electrolysis conservation techniques, proper storage of your "new-born" iron artifacts will ensure that your collection will cheer you for many years!